hydraulic tube Fittings manufacturers in India, hydraulic fittings manufacturers in India, pipe clamps manufacturers in India, pipe flanges manufacturers in India, coupling products manufacturers

Hydraulic Tube Fittings

Since last four decades, hyloc hydrotechnic pvt. ltd., Belgaum based company is manufacturing these high pressure hydraulic tube fittings.

Many users in hydraulic industry use different terminologies for these tube fittings. Some of the alternates used are like, Tube couplings, adaptors, connectors, flare less tube fittings, ferrule fittings, progressive ring fittings etc.

Hyloc is certified for;

Apart from above management system certifications, hyloc is also approved as ‘TYPE APPROVED’ supplier for marine.

Credentials

Hyloc is active member of BIS (Bureau of Indian standard) and contributes in preparation of technical documents related to Tube fittings for Fluid power sectional committee. PGD 36 is a Technical committee for Fluid power systems.

Hyloc is ‘P’ member of ISO/TC 131 Standardization in the field of fluid power systems and components, comprising terminology, construction, principal dimensions, safety requirements, testing and inspection methods.

Product Basket

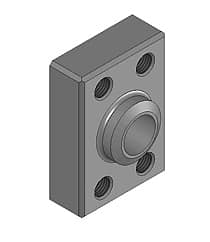

Apart from tube fittings, hyloc manufactures different types of hydraulic valves, pipe flanges, diagnostic couplings and tube/pipe clamps.

Some of the valves manufactured are as below;

Each type of valves has different configurations and sizes. Hyloc manufactures wide range of pipe flanges based on ISO 6162 and ISO 6164 standards. Buttweld, socket weld and blind flanges to suit pipes from ½” NB to 5” NB.

Hyloc make diagnostic couplings are with unique design with ZERO leakage even for low pressure air/gas application. For detailed information, contact our Marketing and sales team.

You can also download our complete Product Catalogue.

Basics of Tube Fittings

Tube fitting consist of three main parts, namely fitting body, coupling nut and a ferrule (which is also termed as cutting ring, progressive ring etc). Tube fittings are suitable for metric size tubes. Imperial size tube fittings are also manufactured by hyloc. Contact our Marketing and sales team for further details.

Original Metric fitting design is based on German standard. i.e. DIN 2353. Later International Standards Organization formed a technical committee and released a standard as ISO 8434 as a basic standard. Tube fittings as a broad term used by different industries with different fitting arrangement based on the application.

Many types are tube fitting designs are available as mentioned below;

ISO has released different standards for all above types of tube fittings.

The design of tube fitting body, coupling nut and ferrules are based on ISO standards. The dimensions and the requirements are well defined by these standards. Some of the key parameters of the fitting design are left to the manufacturer to have their choice of design specifications. Tube fitting body has 24 º cone with excellent surface finish for to get lower friction during assembly and with a provision to receive a tube with metric threads. Coupling nut has also metric internal threads with a support flange inside to drive the ferrule during assembly process. Hyloc Ferrule design is very special in its geometry and metallurgy. The design has TWIN cutting edges which firmly grips the tube after assembly thereby creates a leak proof joint. Hyloc has such tube fittings in many sizes and different configurations. Download our product catalogue for detailed information or contact our Marketing and sales team. For assembly processes, contact our Marketing and sales team.

Material of Construction

The materials used in the manufacturing of these fittings are mainly carbon steel grade. Some of the stainless steel grades of fittings are also manufactured by hyloc. Tube fitting bodies of elbow and tees are hot forged. Coupling nuts are cold forged.

Surface Treatment

Hyloc tube fittings are surface treated with Trivalent Alkaline Zinc and Zinc Nickel for corrosion resistance.

Performance Tests

Hyloc Tube fittings are tested at random to verify their performances under various test conditions. Some of the tests related to fittings are as under.

The above mentioned tests are as per International standards specifications and all the requirements are well adhered to. Hyloc tube fittings are tested for all above tests and our fittings have successfully passed these. Hyloc can demonstrate all these tests since we have a dedicated test lab in house with adequate equipment and tools.

Customized Products

Apart from our standard products of tube fittings, hyloc also makes customized tube fittings to meet customer requirements. We have more than 15,000 products in our basket supplied to many industrial segments so far. If you have any such special requirements, please share the drawings, samples or even your conceptual ideas. We are happy to develop the products as per your needs. Just call our Marketing and sales team.

Infrastructure

Hyloc has complete infrastructure, which includes;

Have any troubles? Leakages in the systems?

If you have any troubles in product selection, assembly and maintenance or if you are facing any leakage issues from existing fittings, machines, we have the right solutions for you. Contact our Marketing and sales team.

Product Training

Hyloc also offers product trainings to assembly team, design and application engineers about the selection of hyloc products, assembly and trouble shooting.

News

Hyloc is a place, where everyone is enjoyed working along with different activities keeping them more energetic, enthusiastic for the whole working time and days. Lot of such programs are arranged in hyloc. We are happy to share this information to our business partners. Visit our ‘NEWS’ tab for more details.

CSR Activity

The establishment of Polyhydron Foundation is another feather in the cap of Polyhydron group. This Foundation was established in 2012. It is the recent innovative step taken by Polyhydron group towards the Corporate Social Responsibility. It is formed with the noble objective of improving the quality of the life, health, education, of all the industrial workers, staff, their families & society at large. Also, to help under-privileged children to transform their lives through good education.

I read your blog.. you have very good content.

ReplyDeleteWe are offering best quality of Ferrule Fittings in Hyderabad